We have a statement that says, “Safety is everyone’s responsibility.” EXAIR builds its name around this by manufacturing safe and protective compressed air products. In the United States, we have an organization called the Occupational Safety and Health Administration (OSHA) that enforces governmental directives for safe and healthy working environments. They do training, outreach programs, and educational assistance for manufacturing plants to reduce injuries and fatalities. They can also enforce these directives with heavy fines for violations. With compressed air systems, the two most common violations are 29CFR 1910.242(b) for dead-end pressure/chip shielding and 29CFR 1910.95(a) for maximum allowable noise exposure.

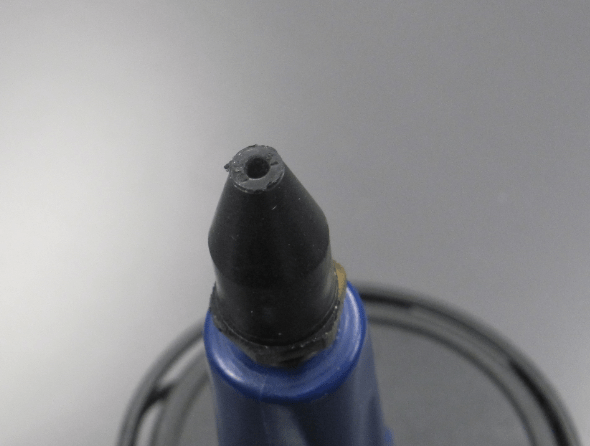

Here is an example of a nozzle that is dangerous. As you can see, there is only one path where the air can pass through and be blocked. Other similar types of blow-off devices that would fall into this same group would include copper tubes, flexible lines, and open pipes. They are dangerous as compressed air cannot escape if it is blocked by your body or skin. If operated above 30 PSIG (2 bar), these nozzles could penetrate the skin and create an air embolism within the body, which can cause bodily harm or death. This is a hazard that can be avoided by using EXAIR Super Air Nozzles and Safety Air Guns. The nozzles are designed with fins, which allow the air to escape and cannot be blocked by your skin. So, you can use the EXAIR Super Air Nozzles safely above 30 PSIG (2 bar) and remain OSHA compliant.

To counteract the dead-end pressure violation, some nozzle manufacturers create a hole through the side of the nozzle (reference photo above). This will allow the compressed air to escape, but now the issue is noise level. With an “open” hole in the nozzle, the compressed air is very turbulent and very loud. The National Institute for Occupational Safety and Health (NIOSH) states that 70% to 80% of all hearing loss within a manufacturing plant is caused by compressed air. OSHA created a chart to show the maximum allowable noise exposure. This chart shows the exposure time and noise limits before hearing protection is required. The EXAIR Super Air Nozzles, Super Air Knives, and Super Air Amplifiers are designed to have laminar flow, which makes them very quiet. As an example, the model 1210 Safety Air Gun has a sound level of only 74 dBA, well under the noise exposure limit for 8 hours.

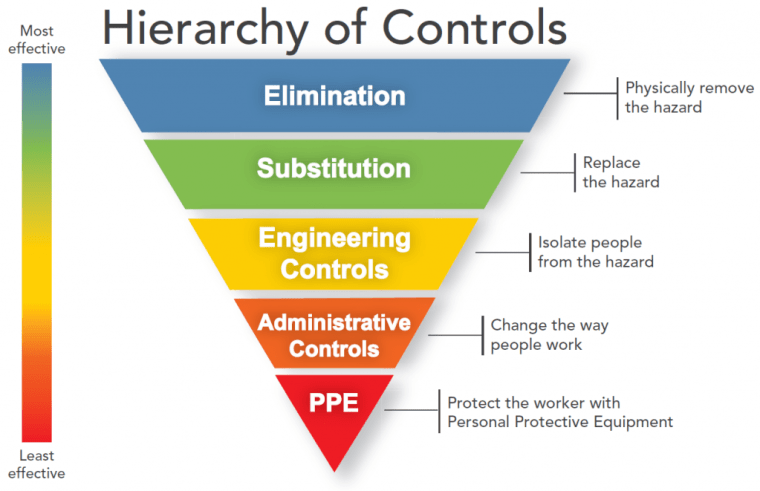

NIOSH created an overview of how to handle hazards in the workplace. They call it the Hierarchy of Controls to best protect workers from danger. The most effective way is by eliminating the hazard or by substituting the hazard. The least effective way is with Personal Protective Equipment, or PPE. For unsafe compressed air nozzles and guns, the proper way to reduce this hazard is to substitute it with an engineered solution.

One of the last things that companies think about when purchasing compressed air products is safety. Loud noises and dead-end pressure can be missed or forgotten. To avoid any future fines or having to purchase additional personal protective equipment (PPE), it will be less expensive and a preferred safety strategy to purchase EXAIR products. As in the above Hazard Hierarchy of Controls chart, EXAIR products are that engineered solution. If you would like to improve the safety of your facility and reduce energy costs, an Application Engineer at EXAIR can review your current blow-off devices. Remember, safety is everyone’s responsibility.

John Ball

Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb

Picture: Safety First by Succo. Pixabay License