The EXAIR Super Air Knives as well as most of EXAIR products have no moving parts! What does that mean, well with no moving parts that means there are no parts to wear out! Other than changing a compressed air filter element here and there (somewhere around $30-$50 bucks) and opening the knife to clean it. That is it!

Blowers on the other hand are a whole different story, there are LOADS of moving parts resulting in downtime and numerous replacement parts. I’m just going to cover the main ones!

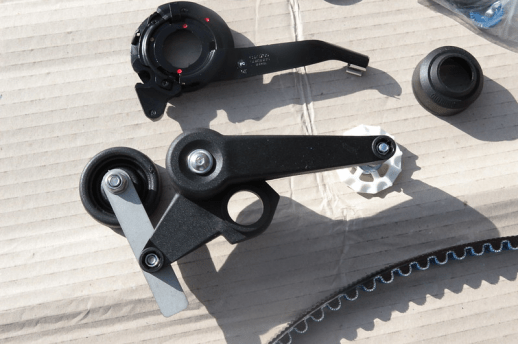

Belts and Tensioners

Just like you car your blower motor and blower heads are connected by a rubber belt and tensioner to keep it tight and clean. Over time since there is so much vibration and movement these belts can start to wear down or tear, leading to a 1-2 Hour downtime to find and repair the issue. The same thing will happen with the bearing in the Tensioners.

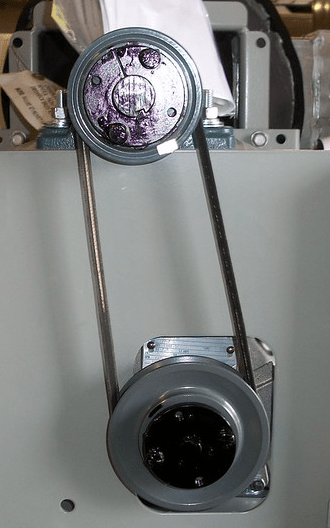

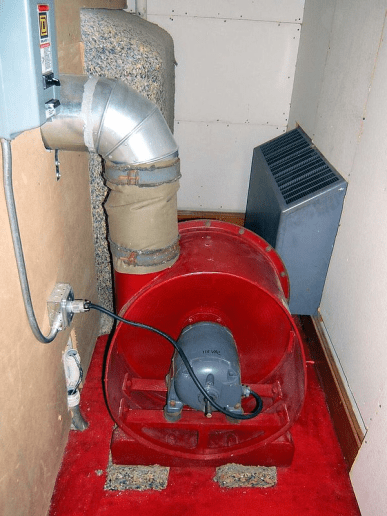

Blower Heads and Motors

All high speed rotating equipment will eventually fail, due to normal wear of seals and bearings. So you either need a spare which can be a pricey investment or your operation will be down until you get it repaired or swapped out by the manufacturer.

Filters

Blowers have an inlet filter installed. However, rather than filtering the compressed air like a compressed air knife (within the enclosed compressed air line) blowers filter the ambient air around the blower (within the application space). So if your facility is dirty and dusty these filters are going to succumb to the various, environmental contaminations rather quickly.

To break that down a little better!

System Maintenance:

- Blower System – The intake filter has to be changed periodically as well as the motor and belt has to be checked as a preventive maintenance. Being that the blower motor is a mechanical device, the bearings and belts will wear and have to be replaced. Without proper maintenance, things can break prematurely. Loss of production will cost your facility revenue on the bottom line.

- Super Air Knife – They do not have any moving parts to wear out. Only compressed air is needed to operate. The maintenance requirement is to change the compressed air filter once a year.

When you bring the whole picture into view the total cost of ownership is quite clear when you look at loss of output, loss of product, and breakdown of equipment. Yes the power generated in some cases by the compressor can be more than a blower. But when you look at purchase price, installation cost, and maintenance, the compressed air operated, Air Knife is the clear winner.

Compressed air can be expensive, but if you use EXAIR products, you can use the compressed air very efficiently. You do not have to sacrifice other areas within the total cost of ownership. If you have a similar application, you can contact an Application Engineer at EXAIR. We will be happy to discuss the benefits of using the EXAIR Super Air Knives over a blower-type air knife.

Jordan Shouse

Application Engineer

Send me an Email

Find us on the Web

Like us on Facebook

Twitter: @EXAIR_JS

Tearing belt image courtesy of jblevine2004 Via Creative Commons

Blower Motor and Head image courtesy of Ragtimer1 Via Creative Commons

Belt Tensioner image courtesy of Cordylus Via Creative Commons