In the world of fluid handling, the effective selection and operation of pumps are crucial for achieving optimal performance. Seepex, a leading manufacturer of progressive cavity pumps, provides pump curves that are essential tools for engineers and operators alike. Understanding when and how to use these curves can significantly enhance system efficiency and reliability. This article explores the importance of Seepex pump curves and the scenarios in which they should be utilized.

What Are Seepex Pump Curves?

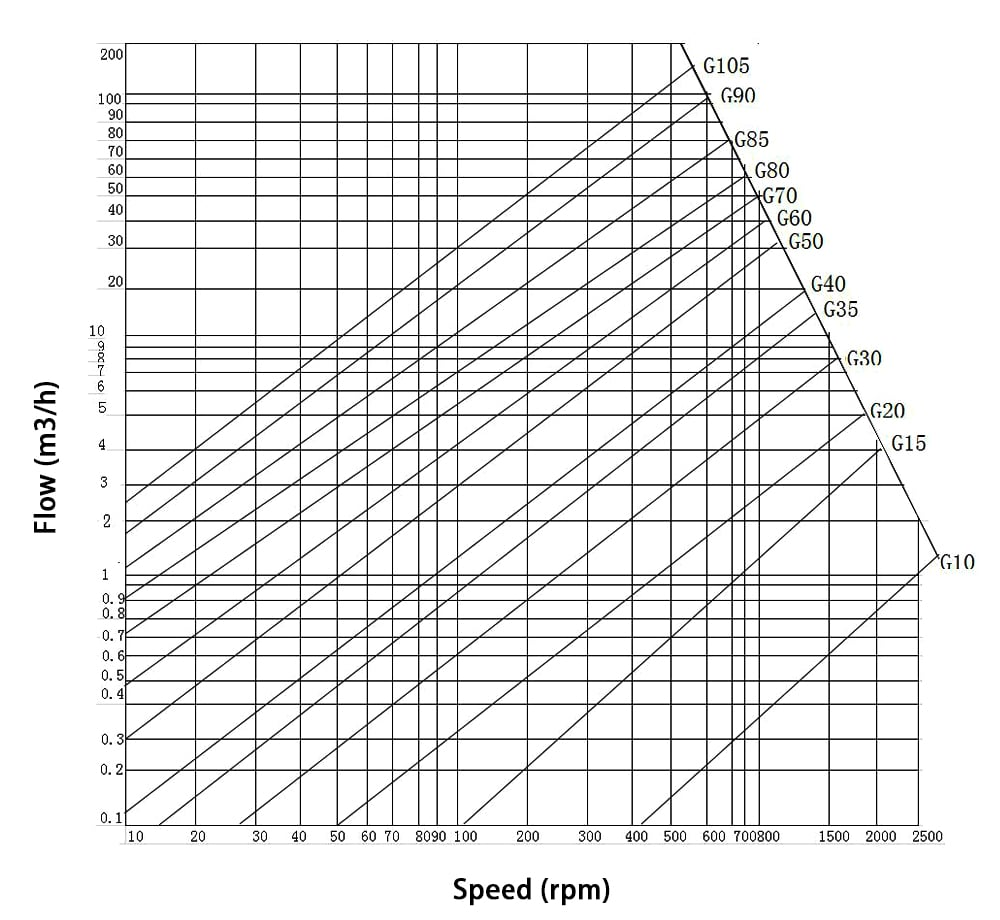

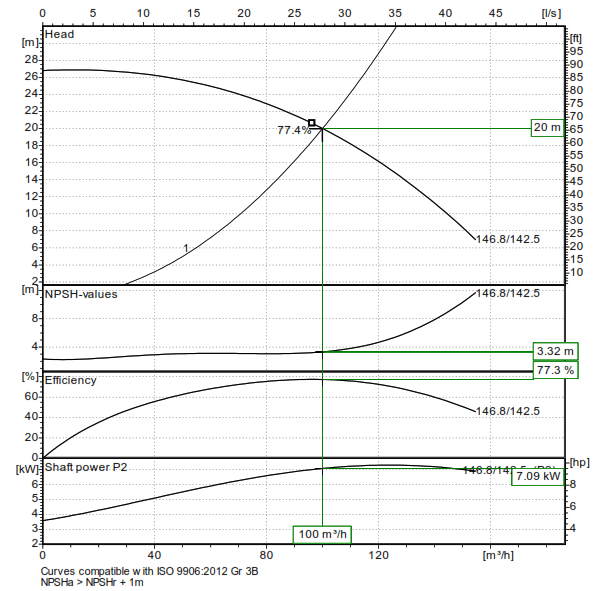

Seepex pump curves represent the relationship between flow rate and pressure within a specific pump model. These curves typically illustrate how the pump performs under varying conditions, helping users understand its capabilities. The curves are generated from extensive testing and provide critical information for selecting the right pump for a particular application.

Importance of Pump Curves

Performance Prediction

One of the primary functions of Seepex pump curves is to predict pump performance. By analyzing the curves, users can determine how a pump will operate under different load conditions. This information is vital for ensuring that the pump can handle the required flow rates and pressures in a given application.

System Design

Pump curves are also integral to system design. Engineers can use them to calculate the necessary pump size and configuration that will meet the demands of the system. This ensures that the pump operates efficiently and reduces the risk of premature wear or failure.

Troubleshooting

In case of performance issues, Seepex pump curves can assist in troubleshooting. By comparing the actual performance against the expected performance depicted in the curves, users can identify potential problems within the system, such as blockages or mechanical failures.

When to Use Seepex Pump Curves

1. Selecting the Right Pump

When considering a new pump installation, it is essential to analyze Seepex pump curves to select the most suitable model. Users should:

- Assess the required flow rates.

- Evaluate the system pressure needs.

- Consider the fluid properties, including viscosity and temperature.

Utilizing pump curves at this stage ensures that the selected pump will effectively handle the application demands.

2. Modifying Existing Systems

If modifications are being made to an existing system—such as changing the fluid being pumped or altering the system layout—consulting Seepex pump curves is crucial. Modifications can impact the pump’s performance, and understanding these effects helps in making informed decisions about whether the current pump can still meet the requirements or if a new pump is necessary.

3. Upgrading Equipment

When planning for equipment upgrades, it’s important to refer to pump curves to understand how the new pump will integrate into the existing system. This includes evaluating:

- Compatibility with existing piping and fittings.

- Changes in system dynamics due to different flow characteristics.

- Potential energy savings from using a more efficient pump.

By analyzing the pump curves, users can ensure a smooth transition during upgrades.

4. Evaluating Performance Over Time

Regularly reviewing pump curves can help in evaluating the performance of existing pumps. Over time, wear and tear can alter a pump’s efficiency. By comparing current operating data with the expected performance from the curves, operators can assess whether maintenance is needed or if the pump is nearing the end of its operational life.

5. Addressing Special Applications

Certain applications may have unique requirements, such as handling abrasive materials or fluids with varying viscosities. In these cases, Seepex pump curves provide insights into how the pump will perform under specific conditions. Users can determine:

- The impact of fluid characteristics on pump efficiency.

- The suitability of different pump models for specialized tasks.

Conclusion

Seepex pump curves are essential tools in the realm of fluid handling, providing valuable insights for selecting, operating, and maintaining pumps. By understanding when to utilize these curves—whether for selecting the right pump, modifying existing systems, upgrading equipment, evaluating performance, or addressing special applications—users can enhance efficiency and ensure reliable operation. In a field where precision and reliability are paramount, leveraging Seepex pump curves is a step towards achieving optimal fluid handling solutions.