Choosing the right spare parts for progressive cavity pumps is crucial for maintaining efficiency and minimizing downtime. Progressive cavity pumps are widely used in various industries for their ability to handle viscous fluids and provide a steady flow. When it comes to OEM (Original Equipment Manufacturer) spare parts, the selection process can be intricate. This article aims to guide you through the essential considerations and steps to select the appropriate parts.

Understanding Progressive Cavity Pumps

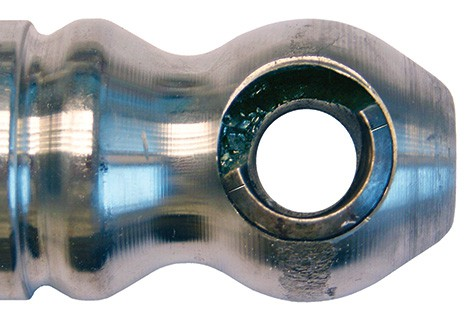

Before diving into spare parts selection, it’s important to understand the components of a progressive cavity pump. These pumps consist of a helical rotor and a stator that work together to create a continuous flow of fluid. The performance of these pumps largely depends on the quality and compatibility of the spare parts used.

Importance of OEM Spare Parts

Choosing OEM spare parts is vital for several reasons:

- Quality Assurance: OEM parts are manufactured to the exact specifications of the original equipment, ensuring optimal performance.

- Compatibility: These parts are designed specifically for your pump model, reducing the risk of malfunction due to incompatibility.

- Longevity: OEM parts typically offer better durability, leading to extended service life and fewer replacements.

- Warranty Protection: Using OEM parts often helps maintain the warranty of the equipment.

Key Considerations When Choosing Spare Parts

Selecting the right progressive cavity OEM spare parts involves several important factors:

1. Compatibility with Pump Model

Ensure that the spare parts you choose are compatible with your specific pump model. Check the manufacturer’s documentation for part numbers and specifications. Using incompatible parts can lead to operational failures and increased maintenance costs.

2. Material Quality

The materials used in the manufacture of spare parts should be durable and suitable for the fluids being pumped. Common materials include:

- Elastomers: For stators, ensure they are resistant to the chemicals and temperatures of the fluids.

- Metals: The rotor should be made of high-quality materials to withstand wear and corrosion.

3. Supplier Reputation

Research and select reputable suppliers for your OEM spare parts. Look for suppliers with positive reviews, established track records, and good customer service. A reliable supplier will not only provide quality parts but also offer support and guidance.

4. Cost Considerations

While cost should not be the sole deciding factor, it is important to consider your budget. Compare prices among different suppliers, but remember that the cheapest option may not always deliver the best value. Focus on the overall cost-effectiveness and longevity of the parts.

5. Availability and Lead Time

Check the availability of the spare parts and the expected lead time for delivery. In critical operations, long lead times can result in significant downtime. Opt for suppliers who can provide timely delivery to keep your operations running smoothly.

6. Technical Support

Ensure that the supplier offers adequate technical support. This can be crucial when you encounter issues during installation or operation. A supplier with knowledgeable staff can help troubleshoot problems and provide valuable insights.

Recommended Spare Parts for Progressive Cavity Pumps

When selecting spare parts, consider the following key components:

- Stators: Choose the right elastomer material based on the fluid properties.

- Rotors: Ensure they are of high-quality material to resist wear and tear.

- Seals and Gaskets: Essential for preventing leaks and maintaining pressure.

- Drive Shafts: Must be compatible with your pump’s motor and assembly.

- Bearings: Important for smooth operation and reducing friction.

Conclusion

Choosing the right progressive cavity OEM spare parts is essential for the efficient operation of your pumps. By considering compatibility, material quality, supplier reputation, cost, availability, and technical support, you can ensure that your equipment runs smoothly and reliably. Investing time in selecting the right parts will ultimately save you money and reduce downtime, enhancing the overall productivity of your operations. Remember, the right spare parts can make all the difference in maintaining the performance and longevity of your progressive cavity pumps.