How is Compressed Air Used to Convey Products?

Compressed air systems are used to convey all types of solids, plastics materials, metal pieces, waste, chip, and trim removal in a manufacturing environment. Internal air conveyor describes items that are moved in the same pipe as the air moving the items. This type of conveyor is used in packaging industries. Since the pressure lessens in the pipe with increased distance, internal air conveyors are limited to lengths of about 100 ft. (30 meters). Sometimes these conveyor systems are referred to as pneumatic conveyors.

In general, pneumatic conveyors easily move items at faster speeds than other types of conveyors. They are also ideal for moving scrap where conventional conveyors would become quickly clogged or contaminated with debris. The inside diameter is recommended to be roughly twice the diameter of the part/material being moved to help prevent clogging. Air conveyors are also useful when transporting sharp or abrasive materials. Metal scrap and recycling centers are perfect places to utilize air operate conveyor because long ribbons of razor-sharp metal can easily snag other types of conveying equipment.

Air Conveyor is most commonly used for moving lightweight objects such as empty containers, boxes, and trays at speeds often exceeding 1,000 fpm, but they are not limited to lightweight materials. Different air operated conveyor systems are designed to convey different types of products and perform various specific tasks. Other common applications include hopper loading (resin in the plastic industry, bottle caps in bottling, etc.), transferring parts from one location to another, tensioning fiber, in filling operations and vent gas in some cases. The gaseous elements are conveyed by the vacuum action and sometimes vented to the atmosphere. Air conveyors are also well suited for handling corrosive or high temperature gas because no electricity is involved, and they can be supplied in appropriate materials. This means that the unit can be customized to meet safety standards and are virtually maintenance free.

How it works?

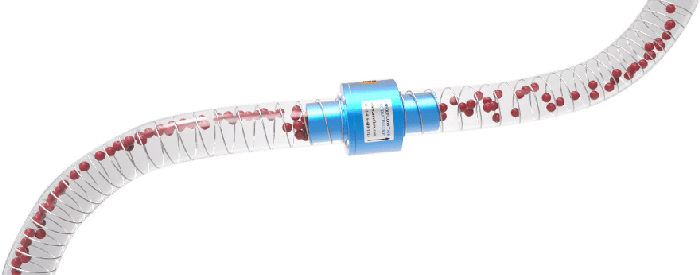

The Ring Vac and XSPC are air operated conveyor units offered by Nex Flow which uses the Venturi effect. The effect is a version of the Bernoulli’s principle which essentially allows it to increase the speed of the flow to maximize conveying efficiency. Refer to this article to learn more about the Venturi Effect.

The air operated conveyor uses a series of holes to blow compressed air in one direction creating a vacuum to draw in and move the gas. The number of holes in the system is dependent on the size of the unit, which pulls the air behind the unit creating a vacuum, drawing in any gasses and then pushes them away. It is an ideal solution for moving gas through longer distances aided by the extra vacuum.

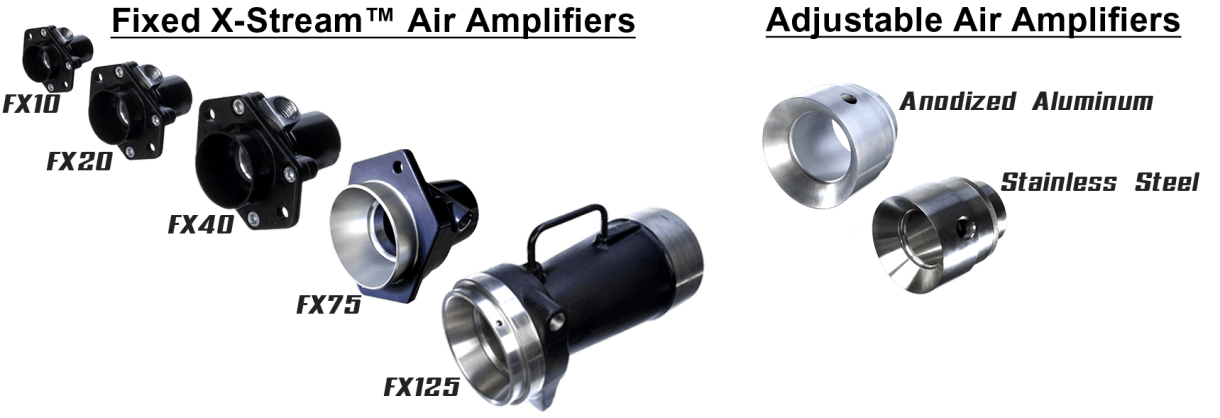

Other than being used to convey products and goods, air conveyors are sometimes used for venting. Typically an air amplifiers is used for venting purposes, but the pneumatic conveyor do offer some benefits especially if the gas is contaminated or that the vented materials could potentially deposit materials on the Coandă angles of the amplifier. Over time, these deposits could stop the amplifier from venting. For air operated conveyors, the compressed air enters through a different vent, so there is less opportunity for dirt deposits if the gas is contaminated. The air operated conveyor produces a higher vacuum but does not move as much air volume as an air amplifier. The Venturi system is a simple unit to manufacture and is lower in cost. It requires less air pressure to operate and is available in aluminum, stainless steel (standard), with special units made in Teflon, and other plastics and metals.

Unlike an air flow amplifier, the Ring Vac Venturi system moves less volume but creates a higher vacuum. Therefore, this system is ideal for venting gas because it is manufactured at a lower cost and it operates at a lower air pressure thereby saving energy. Do note that, the length of the distances transported vertically and horizontally depend heavily on the types of material being conveyed.

Advantages for air operated transporter systems

Significant advantages of using of these systems are their compact size, instant response time, and portability. They are also clean, quick and efficient machines that are designed to transport or vent a wide variety of lightweight products, raw materials, or fumes from one place to another. Air conveyors typically have minimal moving parts and no pockets to collect debris and water, which makes them safe and easy to clean and maintain. Their flow rate is easily controlled with a pressure regulator.

Overall, the air operated conveyor systems are made so they are easy to use, lightweight, maintenance free and does not use electricity. The systems are ideal for both continuous and intermittent use. They are designed to use compressed air efficiently across the entire length and over long distances.

There are several advantages of using Nex Flow air operated conveyor systems (either the Ric Vac or the XSPC conveyors).

The Ring Vacs are primarily used for conveying materials for applications where a vacuum force is beneficial. The Ring Vac moves objects over long distances at high speeds and has an on/off switch to enhance safety. It uses compressed air, not electricity, so there is no explosion hazard. The Nex Flow Ring Vacs are made of anodized aluminum. For high temperature and corrosive applications, regular and high temperature stainless steel are available. When moving food and pharmaceutical products, 316L Stainless Steel pneumatic conveyors are available. Clamp and threaded versions are available so you can simply clamp a standard hose to each end of the Ring-Vac® to start moving things with compressed air.

- Anodized aluminum for most applications – clamp on and threaded versions

- Extra Powerful hard anodized aluminum – clamp on and threaded versions

- Stainless Steel – clamp on and threaded versions for corrosive and high temperature environments

- 316L Stainless Steel – clamp on, threaded, and sanitary flanged versions for food, pharmaceutical and high temperature and corrosive environments.

Similarly, XSPC conveyors are compact, easy to use, portable, and ideal especially for intermittent use in material transfer. It uses compressed air to create a powerful moving force. The inside of the XSPC conveyor is straight and smooth to prevent clogging. The flow is controlled by a regulator making it perfect for non-continuous use and like the Ring Vac pneumatic conveyor – you can simply clamp a hose to each end to start enjoying the benefits of this efficient pneumatic transporter.