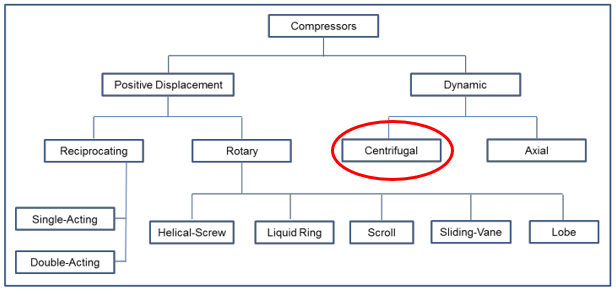

There are two main ways to compress air for supplying pneumatic systems; Positive Displacement and Dynamic. Positive Replacement reduces the volume of air within a confined space to generate pressure. The dynamic type raises the air pressure by using kinetic energy and velocity with rotating impellers that continuously brings in airflow. In this blog, I will cover the centrifugal type of the dynamic branch.

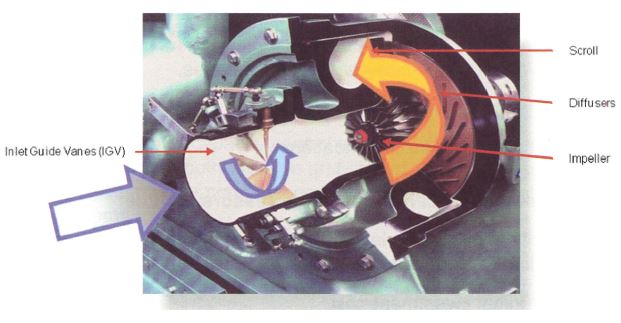

As mentioned, the centrifugal compressor works by transforming kinetic energy and velocity into pressure. Ambient air passes through guide vanes into the center of a rotating Impeller with radial blades and is then pushed outward by a centrifugal force. This radial velocity of air results in an increase in pressure due to kinetic energy. Let’s look at the equation for kinetic energy in Equation 1:

Equation 1:

K = ½ * m * V2

K – Kinetic Energy (J)

m – mass (Kg)

V – velocity (m/s)

As you can see, the energy increases with the square of the velocity. How do we increase the velocity? Let’s look at Equation 2:

Equation 2:

V = w * r

V – linear velocity (m/s)

w – angular velocity (rad/sec)

r – radius (m)

As you can see, as the air travels along the impeller towards the outside, the radius increases. Since the rotations per second are constant, the velocity will increase. In combination with Equation 1, you can see how the energy will increase, thus increasing the pressure.

With the increase in pressure, you will get an increase in heat. It is a natural occurrence with air compressors. Heat from the centrifugal compressor is dissipated with heat exchangers before moving onto the next stage. Multiple stages are required to raise the pressure to a sufficient level for typical industrial plant requirements. The most common centrifugal air compressors have two to four stages to generate pressures up to 100 to 150 PSIG. Centrifugal compressors are near the middle of the road regarding efficiency. Their typical operating cost is 16 to 20 kW/100 CFM.

Advantages:

- Up to 1500 HP systems are available

- Price per Horsepower drops as system size increases

- Supplies lubricant-free air

- Special installation pads are not required for installation

Disadvantages:

- Costs more Initially

- Requires specialized maintenance

No matter the type of air compressor that you use, they are very costly to operate. To help you use them efficiently and safely, EXAIR offers a range of products that can clean, cool, blow, conserve, and convey. This would include our Super Air Knives, Super Air Nozzles, Safety Air Guns, Cabinet Coolers, and much more. If you want to save energy, increase safety, and cut costs no matter what size air compressor you have; you can contact an Application Engineer at EXAIR. We will be happy to help you.

John Ball

Application Engineer

Email: johnball@exair.com

Twitter: @EXAIR_jb

Images Courtesy of the Compressed Air Challenge