It’s not everyday we get to share a customer video of our products in action! But when I get the chance and permission to from the customer you better believe im writing a blog about it!

This was a unique application that took some R&D to figure the perfect amount of spray on a snack crisp to get the desired result. What you see in action below is what they settled on, which turned out to be a EF9040SS!

I wanted to walk you through the selection process for the nozzle we picked, and how we tested different sized caps to get to the end goal!

Let’s start at the beginning! Customer called in to select a liquid nozzle to give a fine coat of a flavoring liquid onto a snack crisp. From the start that is a job for an Air Atomizing spray nozzle, and since the liquid was the viscosity of oil, the external mix was the right style! They said the crisps were moving one by one on a belt with a small gap between each crisp. So we went with the no drip function.

EXAIR’s No Drip Atomizing Spray Nozzles have been engineered eliminate drips; these patented nozzles contain a spring mechanism that when the air pressure reaches above 30 psig the valve will open allowing the liquid to escape out. In this case a solenoid valve is triggered on a timer to open and close based on the presence switch just prior to the nozzle!

Now we moved onto pattern, we knew the crisp was round, and it’s moving by the nozzle at a set speed. So we went with the Flat Fan Pattern to coat the crisps and limit the amount of over spray.

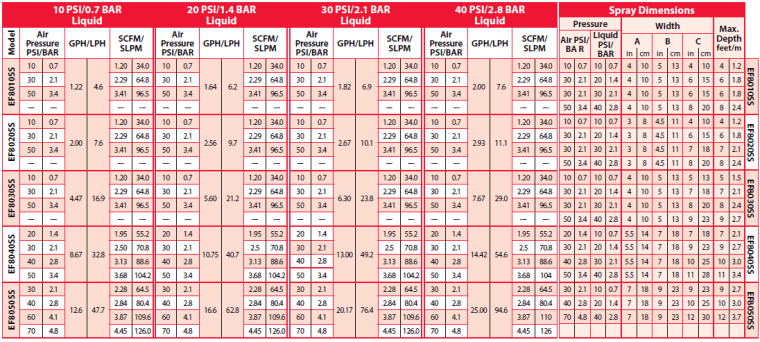

Finally, it came down to volume if liquid they wanted to coat the crisp with, however this wasn’t an easy value for them to know. So to start they bought the smallest GPH No Drip Ext Mix Narrow Angle Flat Fan Atomizing Nozzle we offered and tested! It was working great, but they wanted to coat the crisp a little more and limit the super fine atomization of the oil. So they bought the caps for the size that was 3 higher than they had already tested! And bam you can see in the video its working great!

One hurtle to jump over was since this is an Air Atomizing nozzle it does have some force when it came out of the nozzle. So they were having troubles with the crisp being blown back up line then the nozzle was perpendicular with the belt. When the spray hit the belt it would make a wave of air and liquid that could get under the crisp and cause it to be pushed back. So this fix this I recommended they put the nozzle on a slight angle towards the direction of travel. This allowed the crisp to be pushed down and stay in place rather than be blown back and effecting the amount of liquid that the crisp had applied to it!

At EXAIR, we understand not every application is going to be a cookie cutter application, so you have a team of application engineers at your fingertips that will help you choose the best product for your specific application. Feel free to call or email at anytime.

Jordan Shouse

Application Engineer

Send me an email

Find us on the Web

Like us on Facebook

Twitter: @EXAIR_JS