I am a fan of just about all things MCU (Marvel Cinematic Universe) and have always found Deadpool to be entertaining. Anytime I see a Max Cold Temp or Max Refrigeration mention when discussing or reading about a Vortex Tube I go to a miniature cut scene where Deadpool is saying Maximum Effort as they are fighting the bad guys in Deadpool 2. Enough about my love for MCU, let’s get more into my nerd love for Vortex Tubes.

When it comes to Vortex Tubes and getting the most out of them, EXAIR are the subject matter experts. If you aren’t sure what a Vortex Tube is or how it works, we’ve blogged about that, today’s blog is going to focus more on why you would select a Maximum Cold Temp vs a Maximum Refrigeration Vortex Tube and what actually changes.

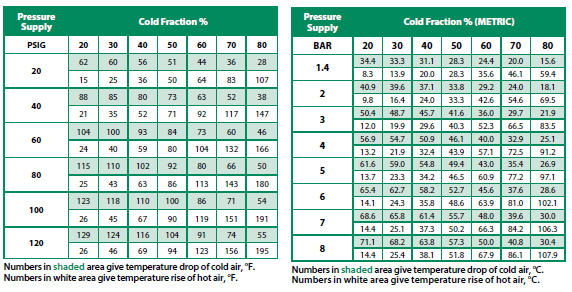

The difference lies in the generator that is inside the Vortex Tube. The reason to choose between the two lies with the application for the tube. In the event that the tube will be used for spot cooling or cooling a small chamber, Maximum Refrigeration generators are desired because you will generally work at a 50% cold fraction or higher. The maximum refrigeration value possible is achieved under set variables such as operating pressure, cold fraction, and incoming compressed air temperature. To see how these effect the cooling performance, check out our blogs on de-rating a Vortex Tube (Part 1 – Part 2). The bulk of applications that I have worked on over the 10+ years I have been part of EXAIR utilize the Maximum Refrigeration Vortex Tube because customers desire to get a product, small area, or component below ambient air temperatures and are going to be operating in the 50% to 80% cold fraction area in order to provide the performance needed.

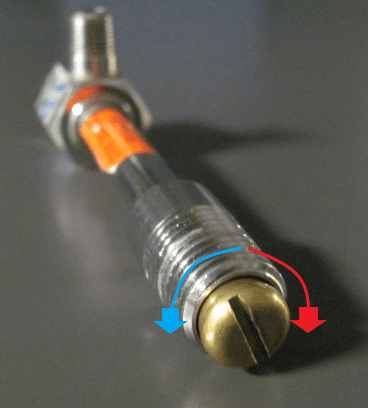

The other small fraction of applications that really need to get the lowest air temperature; in order to get that small component or spot down to -50°F (-46°C) will utilize the Maximum Cold Temperature generators. These will be the 3400 series Vortex Tubes or the “-C” versions. While max cold temperature models are less common, they regularly solve applications for temperature stress testing parts and freeze seals. Maybe you aren’t sure if the Maximum Refrigeration or Maximum Cold Temp is the one you need. That’s where the Application Engineer Team here comes in, hit us up first, and then we can also showcase just how simple it is to change the generator in a Vortex Tube out and give an idea of how many turns out from closed on the Hot Valve you will be to get close to the performance needed.

It truly is just that simple, no internal moving parts, just change out one internal component, and adjust the Hot Valve. To understand how easy that is, check the video below and you can see how big of a swing one can see with adjustments.

Brian Farno

Application Engineer

BrianFarno@EXAIR.com

@EXAIR_BF