Georges-Joseph Ranque was born on February 7th, 1898 in Ambérieu-en-Bugey, France. The son of a railroad engineer, Léon-Joseph Ranque, it was not much of a surprise that he developed a strong interest in physics. An attendee of the prestigious and highly selective post-secondary school, Lycée Saint-Louis, Georges continued to develop his knowledge in the world of physics. From there he was admitted to École Polytechnique where he continued his studies. For years, Georges was interested in the Pantone carburetor. While developing an industrial pump, he noticed the phenomenon now known as the Ranque effect. The Ranque effect is the known working principle for industrial Vortex Tubes. When a compressed gas is injected into the tube tangentially at high velocity, two streams are created: one hot and one cold.

This cold airflow is then utilized throughout a variety of industrial spot cooling and enclosure cooling processes due to its simplicity and reliability. All that’s needed is a supply of compressed air. In 1931, Georges filed for a patent on his vortex tube. His idea didn’t go too far from there, until the topic was later picked back up by another physicist by the name of Rudolf Hilsch. Rudolf made some improvements to the design he called the “Wirbelrohr”, or “whirl pipe” for those not fluent in German. You’ll commonly hear the term “Ranque-Hilsch tube” used synonymously with the term Vortex Tube for this reason.

So how exactly does this thing work? The truth is no one knows for certain, but there is one commonly accepted theory that explains the phenomenon:

Compressed air is supplied into the tube where it passes through a set of nozzles that are tangent to the internal counter bore. The design of the nozzles forces the air to spin in a vortex motion at speeds up to 1,000,000 RPM. The spinning air turns 90° where a valve at one end allows some of the warmed air to escape. What does not escape, heads back down the tube in the inner stream where it loses heat and exhausts through the other end as cold air.

Both streams rotate in the same direction and at the same angular velocity. Due to the principle of conservation of angular momentum, the rotational speed of the inner vortex should increase. The best way to illustrate this is in Olympic Figure Skating. As the skater is wider, the spinning motion is much slower. As she decreases her overall radius, the velocity picks up dramatically and she spins much quicker. In a Vortex Tube, the speed of the inner vortex remains the same as it has lost angular momentum. The energy that is lost in this process is given off in the form of heat that has exhausted from the hot side of the tube. This loss of heat allows the inner vortex to be cooled, where it can be ducted and applied for a variety of industrial applications.

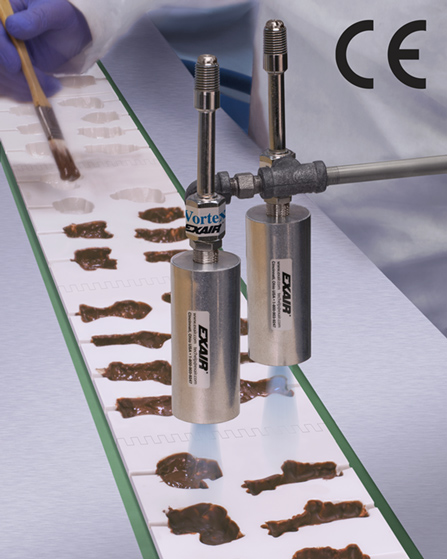

This Vortex Tube theory is utilized in basic Vortex Tubes, along with a variety of other products that have additional features specific for your application. EXAIR’s line of Cabinet Coolers, Cold Guns, Adjustable Spot Coolers, Mini Coolers, and Vortex Tubes all operate off of this same principle.

If you’re fascinated by this product and want to give it a try, EXAIR offers an unconditional 30-day guarantee. We have them all in stock and ready to ship as well, same day with an order received by 2:00 ET. Feel free to get in contact with us if you’d like to discuss how a vortex-based product could help you in your processes.

Tyler Daniel

Application Engineer

E-mail: TylerDaniel@EXAIR.com

Twitter: @EXAIR_TD