If you’re a registered user on our website, you likely got word of this already through our August 15, 2023 Press Release. If not – or even if you did and want some more details – read on, and I’ll tell you all about it.

Like all of our previous catalogs, Catalog #35 provides specification, dimensional, and performance data on all of our stock products. Many of them include detailed descriptions of “textbook” applications for those products. You’ll also find:

- Efficiency Lab (page 6): If you want a full performance report on a compressed air device you’re using right now, this is a free service we offer. Contact an Application Engineer and arrange to have it sent in. We’ll test it for compressed air consumption, force applied, and sound level, and send you a report on it. It’ll include, of course, the EXAIR engineered product(s) that we’ll recommend, along with performance data on them, as a comparison.

- Our Six Steps (page 7): The first page of our Optimization section details the Six Steps To Optimizing Your Compressed Air System. It’s not necessary to follow them in order, and not all of them are applicable to every single compressed air system. But if you’re serious about reducing your compressed air costs, this is a comprehensive plan on how to do it for sure.

- OSHA Maximum Allowable Noise Exposure table & typical Air Consumption values of common “homemade” blow offs (page 53): We put this here so you can turn the next few pages and see what a difference engineered products like EXAIR Super Air Nozzles can make.

- Droplet Size data (page 98): Use this to determine the suitability of our Atomizing Spray Nozzles for liquid spraying applications.

- Vortex Tube Specification and Performance tables (pages 201-202): If you know how much cold air flow you need, and at what temperature you need it, you can use these tables to determine which EXAIR Vortex Tube (or other Spot Cooling Product) to use.

- Cabinet Cooler System Sizing Guide (page 220): Just fill in the blanks & send this in, and we’ll quickly & accurately calculate the heat load of your electrical/electronic enclosure, and specify the right Cabinet Cooler System for you.

Now, if you’ve ever had any of our previous catalogs, you might have noticed that those were already in there, and that’s all pretty great. What’s REALLY great about Catalog #35, though, is some of the new features:

- Line Vac Conveyance Data (pages 176-177): While there’s WAY too many variables in bulk conveyance applications to accurately calculate conveyance rates. We’ve done some controlled, in-house testing with several different materials, several different Line Vacs, at several different lengths & heights, though, and we’re proud to publish that in the new catalog. This shouldn’t be considered a guarantee of performance, but if you’re wondering how much of a particular bulk material you can convey, this table will certainly get you in the right ballpark.

- Best Practice for Using EXAIR Intelligent Compressed Air Products (pages 239-240): This information has always been in the Air Data files on our website, along with an ABUNDANCE of data that’ll help you get the most out of your compressed air system. Now, it’s at your fingers.

Of course, I’d be remiss if I wrote a whole blog on the new catalog without mentioning the new products:

- Model 9207 Ultrasonic Leak Detector (pages 18-19): This serves the same function as the now-obsolete Model 9061, but with some handy upgrades like a LED display, a sleek new body, and high quality ear buds.

- 1/2 NPT HollowStream Cone Atomizing Nozzles (page 105): With five new distinct models at the high-flow end of our already comprehensive line of Liquid Atomizing Spray Nozzles, these provide up to 53 gallons per minute of liquid flow, and are capable of passing particulate up to 0.344″ in diameter.

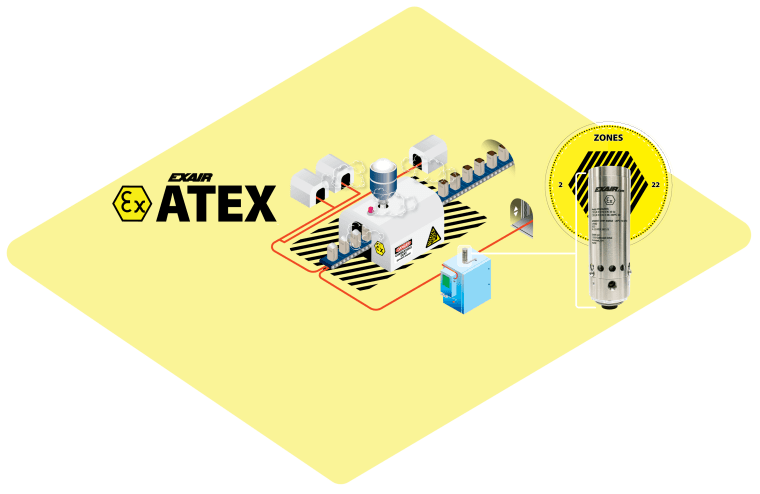

- ATEX Cabinet Cooler Systems (pages 228-229): Like our HazLoc Cabinet Cooler Systems, these have passed thorough testing by UL. While the HazLoc products meet the NEC requirements for Class I Div 1, Class II Div 1, and Class III for UL Classification in the United States & Canada, these meet the stringent requirements required for ATEX approval in Zones 2 & 22, as directed by the European Union.

Like our previous catalogs, Catalog 35 is now available for download (in product line sections due to file size) from the PDF Library at EXAIR.com. You can also request a copy to be mailed to you, or you can contact an Application Engineer to have individual product line sections (again, because of file size) email to you right away.

As always, if you’d like to talk about how to get the most out of your compressed air system, our team of Application Engineers are here Monday to Friday, 7am to 4pm Eastern, to help with that. Give me a call.

Russ Bowman, CCASS

Application Engineer

Visit us on the Web

Follow me on Twitter

Like us on Facebook